Improving the performance of Industrial Athletes

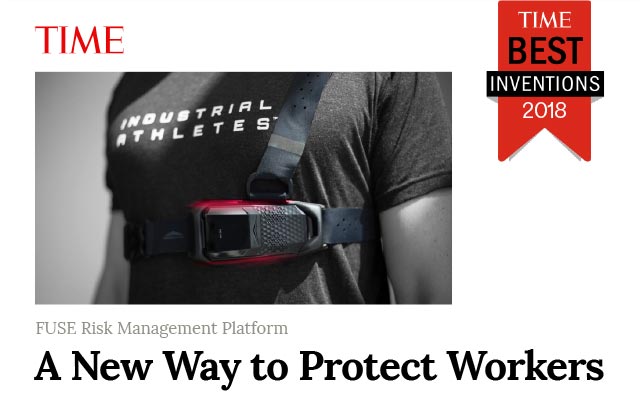

StrongArm's SafeWork Platform combines IoT sensors with Micro Learning & frontline coaching tools to drive industrial facility performance. Tens of thousands of Industrial Athletes™ and their managers rely on our SafeWork Platform everyday to optimize safety & productivity

Keep Every Industrial Athlete

Proud, Protected, & Productive

Who We Are

Our Values are

Get Stuff Done

We are a team of action-takers.

Purpose Driven

Beyond the pursuit of profit, we are purpose-driven.

People-Oriented

People are at the heart of everything we do.

Relentless Improvement

Complacency has no place.

Milestones

Feb 2012

June 2015

July 2016

July 2017

July 2017

Dec 2017

April 2018

Dec 2018

March 2020

April 2020

Dec 2020

May 2021

Jan 2022

May 2022

April 2023

April 2024

Leadership Team

| Sean Petterson | Chief Executive Officer & Founder |

|---|---|

| Mike Kim | Chief Product Officer & Co - Founder |

| Alex Teller | Chief Commercial Officer |

| Matt Spradley | Chief Technology Officer |