Can Wearables Prevent Warehouse Injuries?

PetSmart Partners with StrongArm to Improve Safety and Reduce Injury Costs

For the past two decades, the safety industry has achieved commendable progress in reducing musculoskeletal disorders (MSD) injuries in warehousing and similar operations. However, this success story is facing a new challenge due to significant shifts in the warehouse environment. While MSD Days Away From Work (DAFW) injury frequency has decreased by 20% since 2011, warehouse labor has seen a remarkable threefold increase in the same timeframe. This disparity highlights a potential vulnerability in current prevention strategies.

Further complicating the issue is the rising cost of medical care. Medical inflation has outpaced injury reduction by a significant margin, with a 30% increase in medical expenses since 2011. Additionally, MSDs themselves remain a vital concern, constituting a staggering 42% of all Days Away, Restricted, or Transferred (DART) cases.

This case study explores a novel approach to safety engagement through a partnership between PetSmart and StrongArm. Recognizing that the future of safety requires a multifaceted strategy, this collaboration emphasizes continuous improvement, digital training tools, prioritizing employee engagement, and individualizing behavioral change. We will delve into the details of this partnership and analyze how it aims to address the challenges of the evolving warehouse landscape while ensuring worker safety and well-being.

30-Day Pilot for New Hires

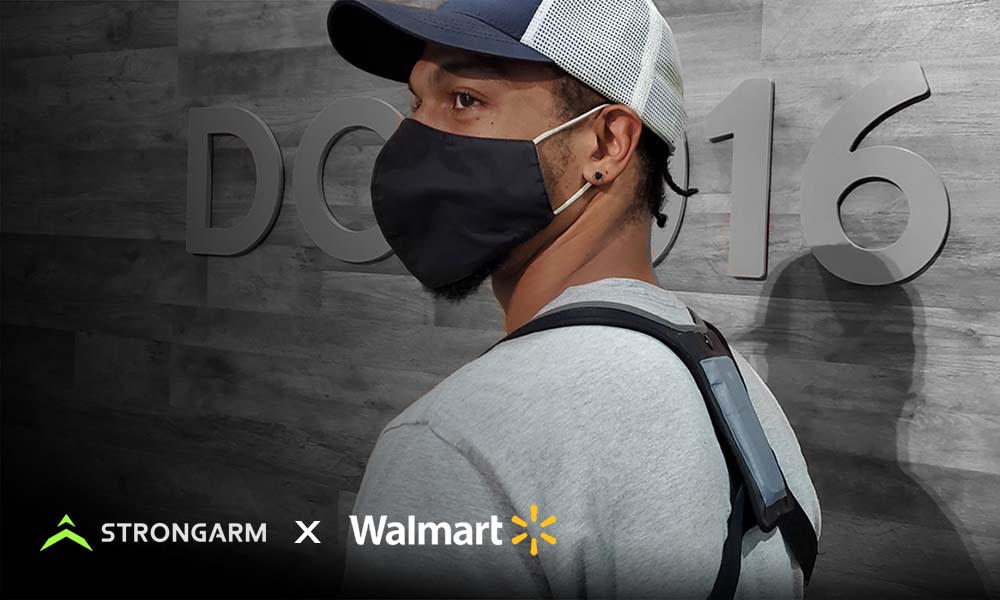

StrongArm uses a uniquely effective system of safety wearable technology and individualized training to improve proper movements and reduce the risk of injuries. To evaluate whether or not StrongArm’s solution could be effective for PetSmart, the company embarked on a 30-day pilot with 50 users across high-risk job tasks.

The results were remarkable. Within a month, participants performed half the number of High-Risk Bends (defined by StrongArm as bending over 70 degrees forward) per hour, and 76% said the SafeWork program made the distribution center a safer environment. PetSmart decided to deploy the program to the entire network, focusing on New In Role (NIR) associates with the highest rate of MSD injuries. This expansion involved seven distribution centers, 300 sensors, and NIR associate participation for 60 days.

Full Program Deployment Results

Six months into the full program deployment, 685 participants over 7,236 shifts engage with the wearable and training. The first 30 days for each participant were considered a baseline period; participants did not receive intervention during data collection.

The results were conclusive; PetSmart’s partnership with StrongArm has significantly reduced musculoskeletal disorders (MSDs) by 56% compared with the average across the same period over the previous four years. Additionally:

- By wearing the sensor for at least 12 sessions, new employees demonstrate a 27% decrease in high-risk bends (see below).

- The average forward bend angle decreased by 10%, indicating an overall improvement in bending posture.

- The program fostered a 25% reduction in the average number of bends per hour, likely due to increased awareness and ergonomic practices.

These positive trends strongly suggest that the StrongArm intervention program has improved PetSmart employees’ workplace safety.

The Finer Points

- Approximately 170 employees participate in the program monthly, for about three sessions per week.

- Most participants are in the “Orderfill Rack” job function.

- Haptic feedback (vibration alerts) is a significant driver behind the decrease in High-Risk Bends.

Lessons Learned

30-Day Pilot

PetSmart analyzed the successes and challenges experienced during the pilot period to ensure a productive full deployment. Some of those lessons included:

Leadership Engagement

Involving leadership from several vital stakeholder groups contributed significantly to the program’s success. These stakeholders included HR, Legal, Operations, Risk Management, IT, and others responsible for education and training.

Establishing the Baseline

During the pilot period, working with PetSmart, StrongArm established a benchmark to measure results against by creating a baseline for new employees by collecting data through the sensors for 30 days before beginning training interventions. It was also essential to start new hire onboarding with a safety assessment. PetSmart management noted that new hires commented that the program demonstrated safety was an important priority for the company.

The baseline included establishing StrongArm Safety Scores for new hires. The Safety Score is a numeral rating between 0 and 100 (high risk to low risk), evaluating bends, tilts, twists, lift rate, and lift weight.

Haptic, Not Biometric

Employees are often concerned about privacy and autonomy, so there were initial concerns about the sensors providing instant behavioral feedback via vibration alerts. PetSmart took care to help employees understand that the vibrations were haptic alerts and not indications of location tracking or other more invasive tactics.

Communication and Celebration

PetSmart wisely decided that more communication helps adopt and understand the program—from warehouse floor to c-suite. Communications can and should include FAQs, ergonomic learnings, ROI updates, behavior change trends, and other metrics. As the program progressed, integrating celebrations of 30/60/90 milestones became essential to reinforce the progressive safety focus.

It was also essential to pay attention to describing the program. PetSmart emphasizes that the wearable safety sensors are essentially digital PPE, making them more likely to be accepted and worn.

Progress Sessions

Progress Sessions are a valuable tool to assist managers during coaching sessions with employees and have a measurable impact on improving Safety Scores and reducing injury risk. The sessions enhance communication between managers and workers while reinforcing established workflows such as safety observations.

Other StrongArm customers have seen a significant correlation between increased Progress Sessions and decreased High-Risk Bends per hour. PetSmart intends to use Progress Sessions to drive cultural change and encourage increased engagement from coaches/managers. Most recent new hires see a 20% reduction in High-Risk Bends while increasing productivity over their first 13 weeks.

Next Steps

The quality of data gathered—and results experienced—encourages PetSmart to continue the StrongArm program and begin using it in ways that will inform future optimization efforts and decisions. For instance:

- PetSmart can deploy wearable technology by zone, job function, and distribution center to pinpoint and improve areas of high risk.

- Year-over-year data on new hires informs trends on growth, retention, and other key HR metrics.

- Data currently proves that StrongArm reduces the risk of injury. Incorporating regular data review helps spot rising risk trends and alerts management when a distribution center or job function needs evaluation.

- PetSmart is poised to use data analysis beyond risk avoidance, including high-level decisions about areas to consider first for automation investments.

PetSmart views its partnership with StrongArm as a long-term exercise in change management and identifies critical pillars of success:

- Leadership support and advocacy.

- Training an internal SME team to execute the StrongArm system.

- Rich and frequent communication across the organization, from onboarding to ROI.

- Celebrating daily, weekly, and monthly successes.

The PetSmart and StrongArm partnership is a compelling example of how a comprehensive approach to safety engagement can address the evolving challenges of the warehouse landscape. By prioritizing continuous improvement, leveraging digital training tools, fostering employee engagement, and tailoring interventions to individual needs, this collaboration significantly reduces MSD risks while promoting a more productive and positive work environment. This case study’s findings can inform future safety practices within warehouses and inspire further innovation in worker well-being and injury prevention strategies.

What makes a “High-Risk Bend” high risk?

StrongArm defines High-Risk Bends as bending over 70 degrees forward while executing a task. Why is this an essential metric in employee health and safety? Occupational Health & Safety (OHS) magazine states the spine is a fulcrum. Body weight—plus the weight of anything lifted—is balanced on one side, and the lower back muscles pull on the other. Bending forward even a few inches causes leg and lower back muscles to pull on the upper body with about 100 pounds of force to maintain balance. And that’s only bending forward a few inches and holding no extra weight.

Bending over 70 degrees to place or pick up a 25 lb. item can require back muscles to pull with 300-500 pounds of force on the lower back. Repeating this range of motion causes muscle fatigue, raising the risk of injury. According to OHS, “Bending and moderate lifting exposes workers to risk for an injury that could not only prevent them from working today but also risk plaguing them with a lifetime of chronic back issues.”

Why is reducing Average Bends Per Hour a good idea?

Reduced Musculoskeletal Disorders (MSDs): Frequent forward bends put strain on the back, shoulders, and knees, which can lead to MSDs over time. These can be painful and debilitating injuries that can cause workers to miss work and incur medical expenses. By reducing bending, you can significantly decrease the risk of these injuries.

Improved Ergonomics: Frequent bending indicates proper ergonomics was not a factor in task design. Warehouses that reduce bending have implemented ergonomic solutions like adjustable workstations, lifting equipment, or improved product placement. These design choices create a more comfortable work environment that can also lead to the following:

- Increased Productivity: Less time spent bending translates to more time spent on productive tasks like picking, packing, and shipping.

- Reduced Fatigue: Constant bending can fatigue workers, leading to slower work and a higher risk of errors. A more ergonomic approach can help workers maintain their energy levels throughout the shift.

- Improved Morale: Workers who feel comfortable and safe are generally happier and more engaged.

Overall Efficiency: By reducing bends, warehouses can streamline processes and optimize worker movements, which leads to faster order fulfillment times and a more efficient overall operation.