Understanding Safety Sensors and Haptic Feedback

What are safety sensors?

Safety sensors can seem like an unknown and complex addition to your workplace, but they’re actually very straightforward and will pay dividends towards injury reduction and operational productivity.

At their core, safety sensors are wearable devices that can detect and mitigate risk of injury in your workplace. Our Flex sensors are small devices – about the size of a deck of cards – that can be clipped to the hip or the torso, or worn in our shoulder harness or x-pack, and function to monitor the movement of Industrial Athletes™.

The everyday duties of these workers can be very physically demanding and there are constant operational risks. Ergonomic injuries, such as lower back injuries and repetitive motion strains (commonly referred to as musculoskeletal disorders, or MSDs), are the most common workplace injury requiring time off within industrial environments.

Our safety technology exists to ensure every employee is using their body in the safest way possible to preserve their health and wellbeing, and avoid these accidents. They do this by providing real-time haptic feedback (or vibrational alerts, explained more below), as well as advanced IoT analytics from the data they collect.

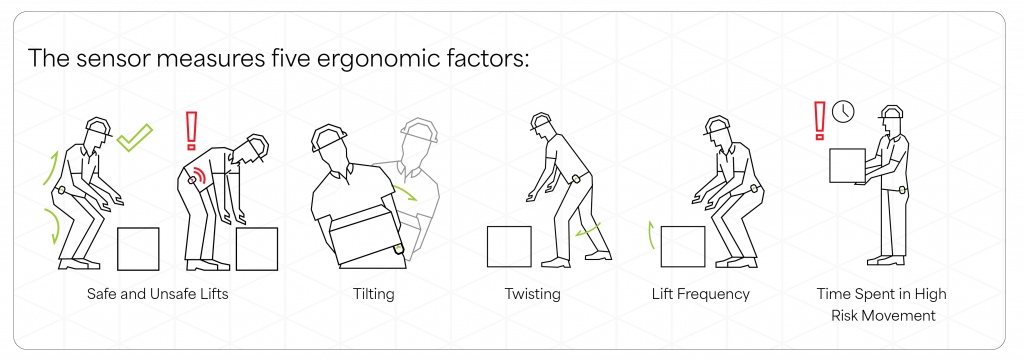

Our haptic sensors contain a nine-axis IMU (Inertial Measurement Unit) which contains an accelerometer, gyroscope, and magnetometer. Together, these measure angles and speed and capture all data necessary for our safety analytics, including the Safety Score and detailed risk analysis.

What is real-time haptic feedback?

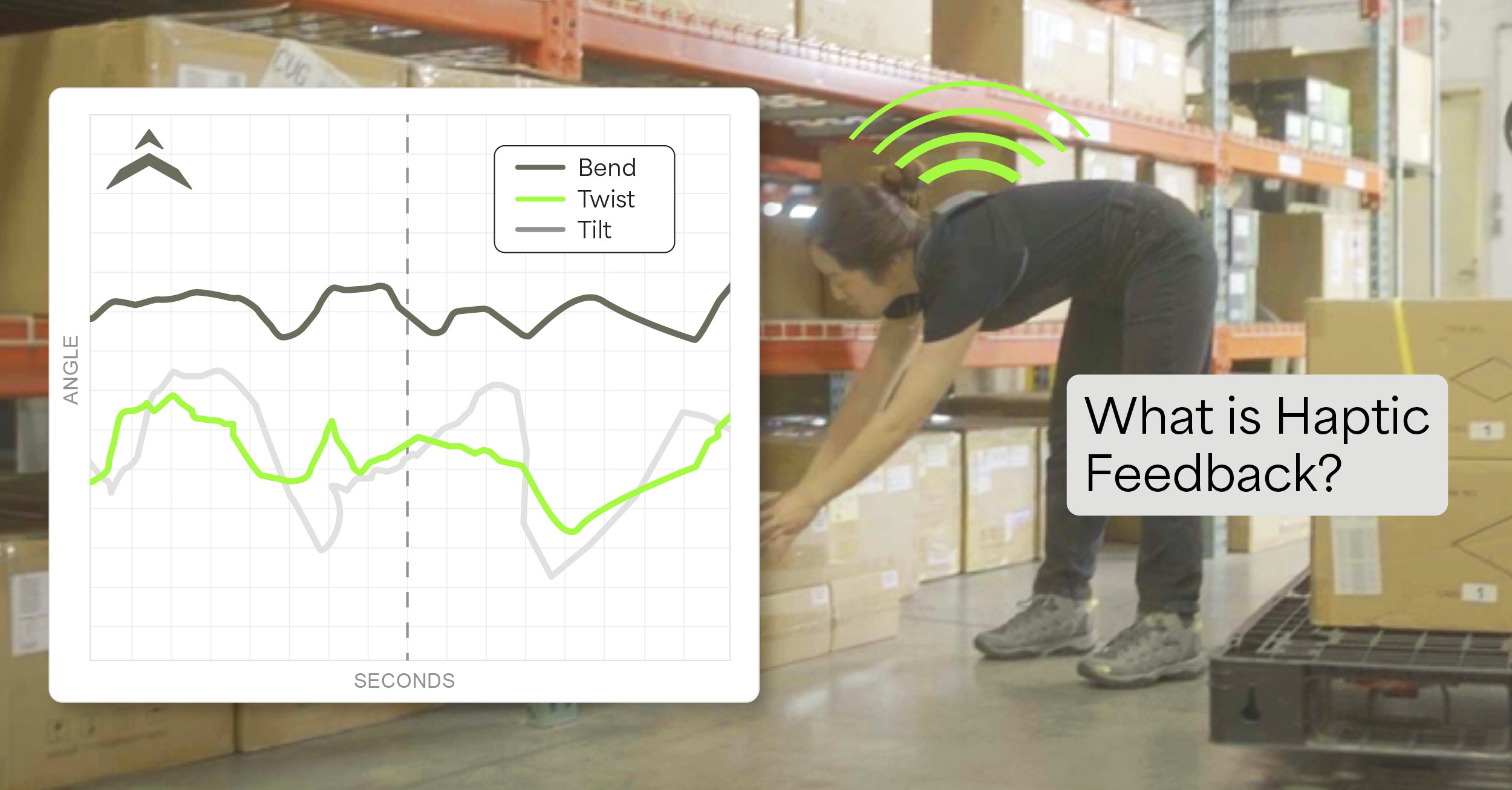

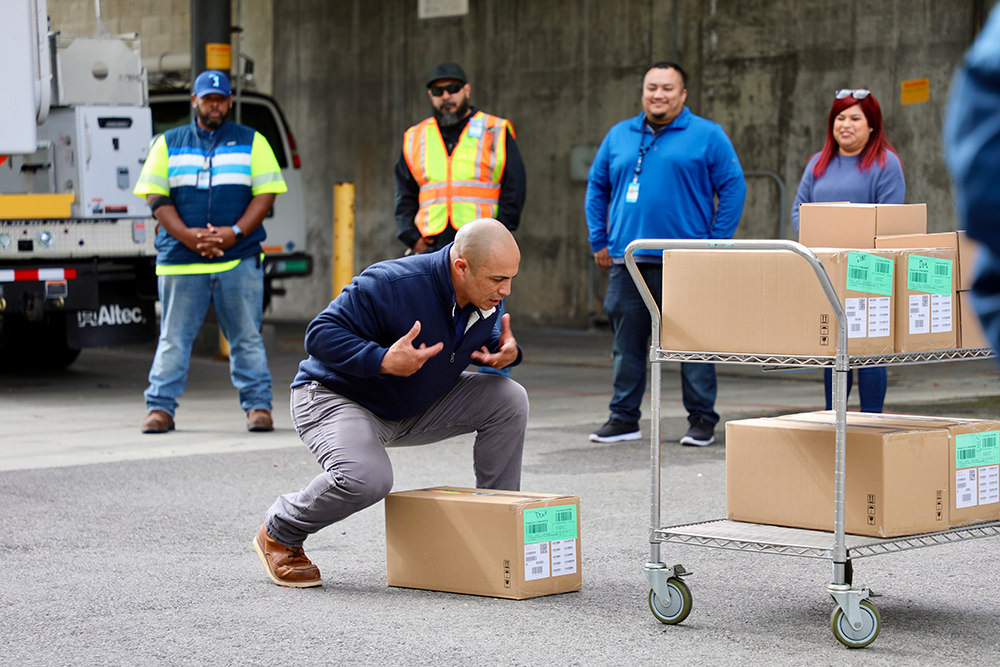

Simply put, ‘haptic feedback’ is the vibrational alerts Fuse and Flex sensors emit when they detect a series of bad bends, fast twists, and so on. For example, if you are wearing a Flex sensor across your chest and continuously bend your lower back over 70º to pick up a product instead of using your legs, your haptic sensor will detect multiple bad bends and you will feel the haptic feedback notifying you of the physical risk – an indication to correct your form.

These alerts can be customized based on job function, facility and individual to ensure that haptic feedback is effective for each cohort and to avoid haptic fatigue. Additionally, each buzz is recorded and this data is transmitted to our servers when the sensor is checked out. From there, the data is analyzed by our AI analytics system to detect troubling trends so we can provide solutions, ranging from simple health and safety tips such as proper lifting technique to operational risk engineering that can help your team mitigate these repetitive dangerous movements.

How can they help you?

The SafeWork System and our safety sensors are proven to reduce workplace injuries by an average of 52% and save you money while doing so (on average, our customers experience a 250% year-over-year return on investment).

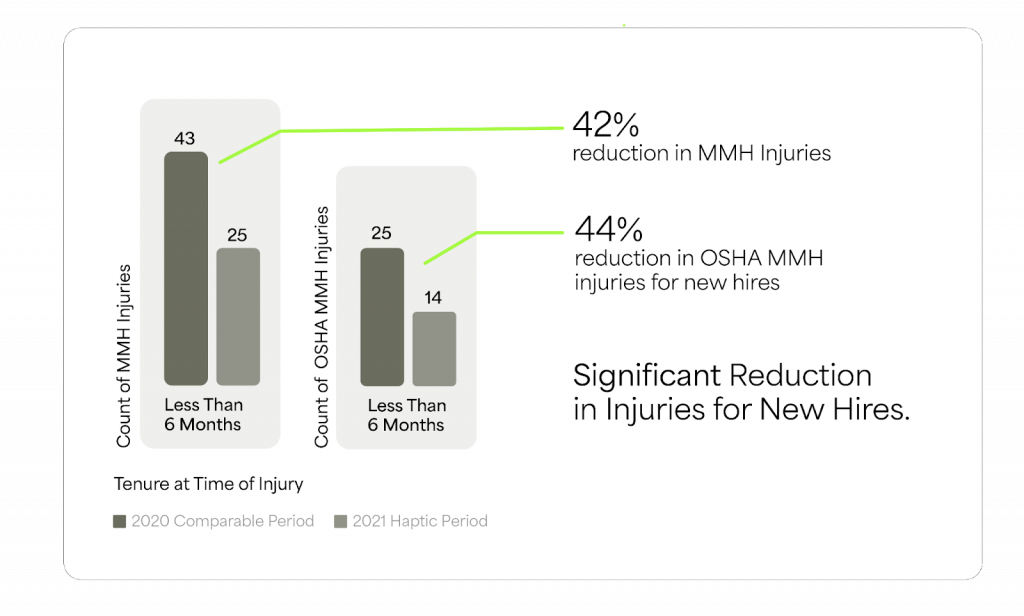

For example, in the graph below, one of our customers identified new hires as particularly at-risk of work-related MMH injuries. In a comparable period of 2020, prior to their partnership with us, employees with less than six months of experience were injuring themselves at a significantly higher rate than more tenured employees. In 2021, when we enabled haptic feedback through the SafeWork System and our safety sensors, participating sites saw a 42% decrease in overall MMH injuries.

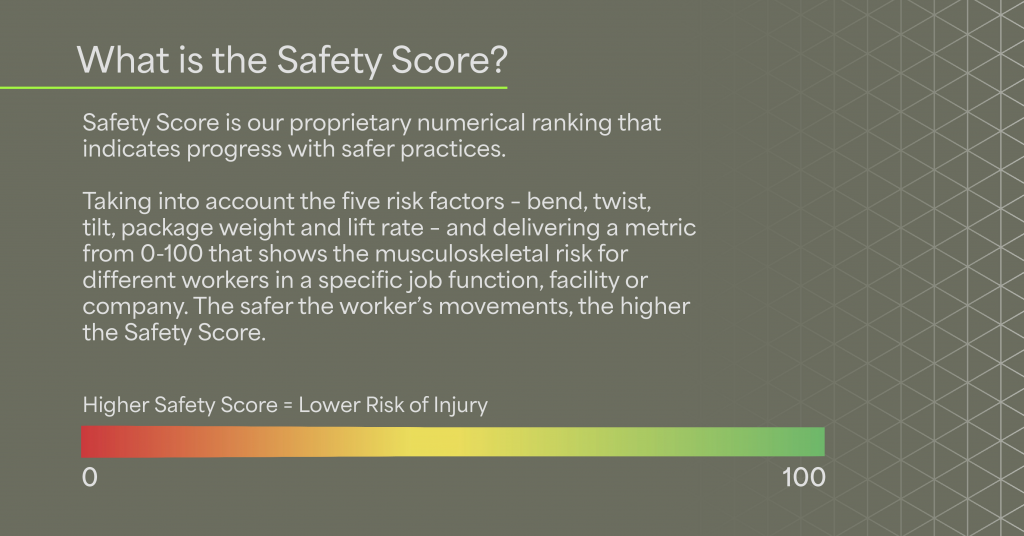

The SafeWork System introduces a variety of new metrics into your workplace that enable you to monitor safety. Risky bending and twisting, unsafe lifting, number of feedback alerts, detailed time of day analysis, percent of time spent at risk, Safety Score – our proprietary indicator for progress with safer practices – and so many more metrics are available at your fingertips to highlight opportunities for improvement within your facility.

These metrics, captured by the sensor, help you identify differences in risk across individuals, job functions or facilities. They can also be employed to discover and prevent immediate risk, or they can be used to detect where facilities need to be redesigned to enhance safety further.

Furthermore, delivering timely injury prevention and risk management is powerful in its own right, but the ripple effects go deeper.

The SafeWork System is the foundation of a positive and proactive safety culture. It enables a cultural shift in peer-to-peer engagement and in how managers can better leverage safety moments with their teams in a more constructive way with lasting impact that goes beyond just safety.

We know your workforce is your most important asset, that is why we continue to build upon our core system to help identify opportunities for process engineering, informed training programs, enhanced productivity and improved retention for a happier, more energized workplace.

Privacy and Data Concerns

We are well aware of the privacy and security concerns that coincide with integrating wearable technology and a data-centric injury prevention program into your workplace. That’s why we have gone out of our way to ensure that we will protect your information and use it strictly and transparently for safety purposes and never punitive action.

Our dataset is designed with data security and privacy top of mind. We are ISO 270001 certified, meaning we rigorously follow the requirements for establishing, implementing, maintaining and continually improving our information security management systems (ISMS).

Furthermore, to make associates more comfortable using our safety sensors, we make it clear that the data recorded while they work cannot be used for punitive purposes. That is to say, we’re not using this information to track or capture unnecessary information from associates (we intentionally omit audio, video and GPS technology for this reason) or ensure associates are working every minute of every shift; we simply keep track of the ergonomic and environmental risk factors listed above to determine safety levels in a facility and provide solutions.

Request a Trial With StrongArm Technologies

With our SafeWork System Activation Program, our team will bring our workplace safety solution directly to you. For just one day, workers will be able to test out our workplace safety wearables and receive real-time ergonomic safety alerts. At the end of the day, management will be provided a real report with intervention opportunities to optimize performance. Request a trial with StrongArm Technologies today.